-

Features

Product Standard

BS EN-1171 / IS-14846

Testing Standard

BS EN 12266-Part 1

Pressure / Class Rating

PN-1.6

Body Material Cum Standard

Cast Iron (IS 210 Gr. FG 200)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem, Handwheel Operated

Type of Seat

Renewable Seat

Type of Wedge

Solid Wedge

Trim

Stem: 13% Cr. (SS 410)

Seat Facing

Cu-Alloy

End Details

Flanged Ends as per IS:1538 PN -1.6 Flat Face (Drilled)

Test Pressure

Body: 2.4 Mpa (Hyd.), Seat: 1.6 Mpa (Hyd.)

Max. Working Temperature

45°C

Notes

Sizes 350mm & above are supplied with Gear

Suitability

Water

Steam

Gas

Oil

Air

-

Material Combination

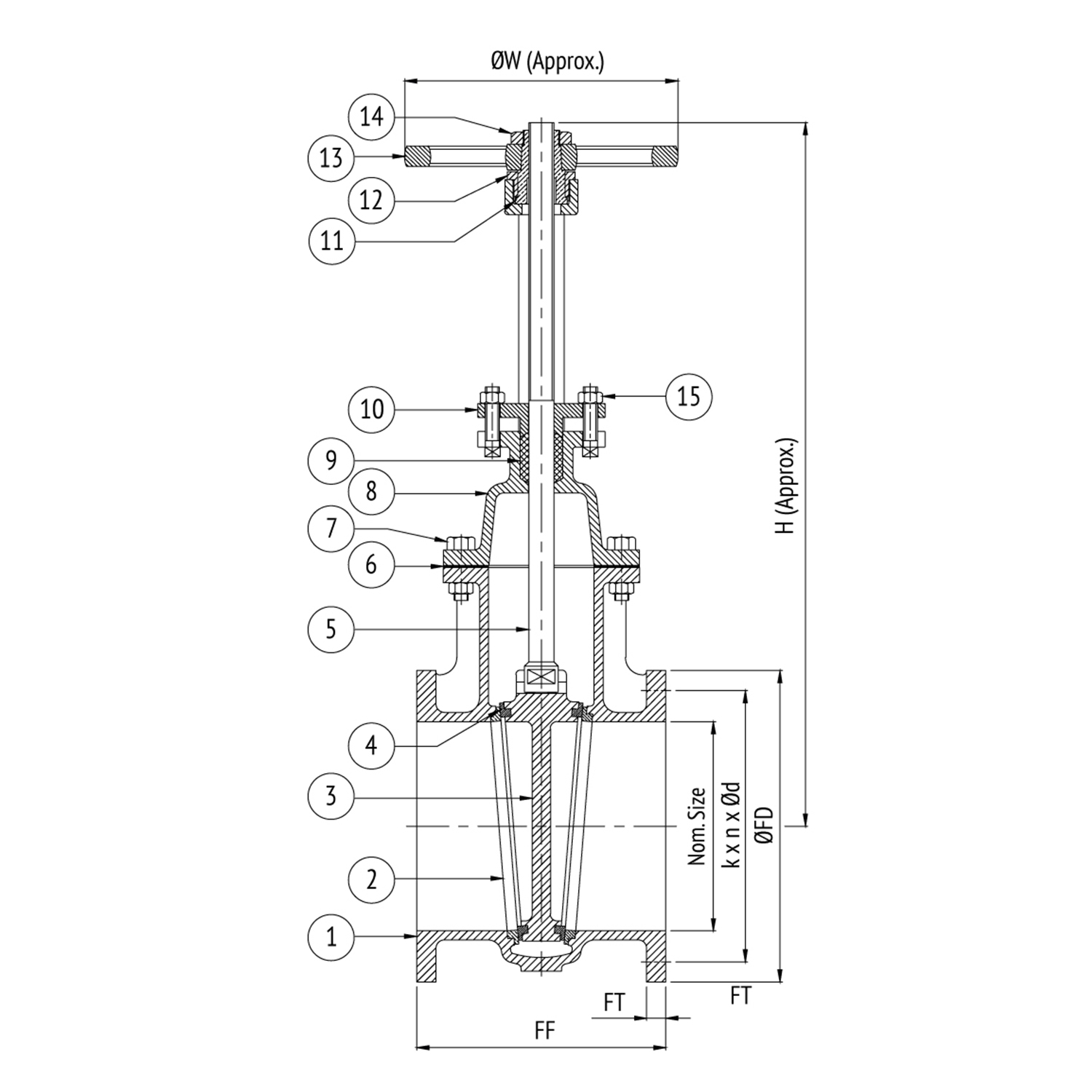

S.No Description No. Material Specifications 1 Body 1 Cast Iron IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220 2 Body Seat Ring 2 Gun Metal IS 318 Gr. LTB2 / BS EN 1982 Gr. CC491K 3 Wedge 1 Cast Iron IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220 4 Wedge Ring 2 Gun Metal IS 318 Gr. LTB2 / BS EN 1982 Gr. CC491K 5 Stem 1 Stainless Steel ASTM A 276 Type 410 6 Gasket 1 C.A.F – 7 Body / Bonnet Bolts & Nuts To Suit Carbon Steel – 8 Bonnet 1 Cast Iron IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220 9 Gland Packing – Hemp & Jute / Non Asbestos IS 4687 10 Gland Flange 1 Cast Iron IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220 11 Yoke Sleeve 1 Bronze / Stainless Steel BS EN 1982 Gr. CC3314 / ASTM A 582 Type 416 12 Yoke Sleeve Nut 1 Carbon Steel – 13 Handwheel 1 M.I. / C.I. – 14 Handwheel Retaining Nut 1 Carbon Steel – 15 Gland Flange Bolts & Nuts 2 Each Carbon Steel – -

Dimensional Data

Size (mm) FF ØW H ØFD FT k n Ød 50 178 225 320 165 16 125 4 19 65 190 225 375 185 16 145 4 19 80 203 225 422 200 21 160 4 19 100 229 320 490 220 22 180 8 19 125 254 320 560 250 22.5 210 8 19 150 267 320 640 285 23 240 8 23 200 292 360 782 340 24.5 295 8 23 250 330 400 1040 395 26 350 12 23 300 356 400 1170 445 27.5 400 12 23 350 381 500 1300 505 29 460 16 23 400 406 640 1370 565 30 513 16 28 450 432 720 1430 615 31.5 565 20 28 500 457 720 1510 670 33 620 20 28 600 508 720 – 780 36 725 20 31

Features

Product Standard

BS EN-1171 / IS-14846

Testing Standard

BS EN 12266-Part 1

Pressure / Class Rating

PN-1.6

Body Material Cum Standard

Cast Iron (IS 210 Gr. FG 200)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem, Handwheel Operated

Type of Seat

Renewable Seat

Type of Wedge

Solid Wedge

Trim

Stem: 13% Cr. (SS 410)

Seat Facing

Cu-Alloy

End Details

Flanged Ends as per IS:1538 PN -1.6 Flat Face (Drilled)

Test Pressure

Body: 2.4 Mpa (Hyd.), Seat: 1.6 Mpa (Hyd.)

Max. Working Temperature

45°C

Product Standard

BS EN-1171 / IS-14846

Testing Standard

BS EN 12266-Part 1

Pressure / Class Rating

PN-1.6

Body Material Cum Standard

Cast Iron (IS 210 Gr. FG 200)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem, Handwheel Operated

Type of Seat

Renewable Seat

Type of Wedge

Solid Wedge

Trim

Stem: 13% Cr. (SS 410)

Seat Facing

Cu-Alloy

End Details

Flanged Ends as per IS:1538 PN -1.6 Flat Face (Drilled)

Test Pressure

Body: 2.4 Mpa (Hyd.), Seat: 1.6 Mpa (Hyd.)

Max. Working Temperature

45°C

Notes

Sizes 350mm & above are supplied with Gear

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

S.No

Description

No.

Material

Specifications

1

Body

1

Cast Iron

IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220

2

Body Seat Ring

2

Gun Metal

IS 318 Gr. LTB2 / BS EN 1982 Gr. CC491K

3

Wedge

1

Cast Iron

IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220

4

Wedge Ring

2

Gun Metal

IS 318 Gr. LTB2 / BS EN 1982 Gr. CC491K

5

Stem

1

Stainless Steel

ASTM A 276 Type 410

6

Gasket

1

C.A.F

–

7

Body / Bonnet Bolts & Nuts

To Suit

Carbon Steel

–

8

Bonnet

1

Cast Iron

IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220

9

Gland Packing

–

Hemp & Jute / Non Asbestos

IS 4687

10

Gland Flange

1

Cast Iron

IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220

11

Yoke Sleeve

1

Bronze / Stainless Steel

BS EN 1982 Gr. CC3314 / ASTM A 582 Type 416

12

Yoke Sleeve Nut

1

Carbon Steel

–

13

Handwheel

1

M.I. / C.I.

–

14

Handwheel Retaining Nut

1

Carbon Steel

–

15

Gland Flange Bolts & Nuts

2 Each

Carbon Steel

–

| S.No | Description | No. | Material | Specifications |

|---|---|---|---|---|

| 1 | Body | 1 | Cast Iron | IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220 |

| 2 | Body Seat Ring | 2 | Gun Metal | IS 318 Gr. LTB2 / BS EN 1982 Gr. CC491K |

| 3 | Wedge | 1 | Cast Iron | IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220 |

| 4 | Wedge Ring | 2 | Gun Metal | IS 318 Gr. LTB2 / BS EN 1982 Gr. CC491K |

| 5 | Stem | 1 | Stainless Steel | ASTM A 276 Type 410 |

| 6 | Gasket | 1 | C.A.F | – |

| 7 | Body / Bonnet Bolts & Nuts | To Suit | Carbon Steel | – |

| 8 | Bonnet | 1 | Cast Iron | IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220 |

| 9 | Gland Packing | – | Hemp & Jute / Non Asbestos | IS 4687 |

| 10 | Gland Flange | 1 | Cast Iron | IS 210 Gr. FG200 / BS EN 1561 Gr. GJL 220 |

| 11 | Yoke Sleeve | 1 | Bronze / Stainless Steel | BS EN 1982 Gr. CC3314 / ASTM A 582 Type 416 |

| 12 | Yoke Sleeve Nut | 1 | Carbon Steel | – |

| 13 | Handwheel | 1 | M.I. / C.I. | – |

| 14 | Handwheel Retaining Nut | 1 | Carbon Steel | – |

| 15 | Gland Flange Bolts & Nuts | 2 Each | Carbon Steel | – |

Dimensional Data

Size (mm)

FF

ØW

H

ØFD

FT

k

n

Ød

50

178

225

320

165

16

125

4

19

65

190

225

375

185

16

145

4

19

80

203

225

422

200

21

160

4

19

100

229

320

490

220

22

180

8

19

125

254

320

560

250

22.5

210

8

19

150

267

320

640

285

23

240

8

23

200

292

360

782

340

24.5

295

8

23

250

330

400

1040

395

26

350

12

23

300

356

400

1170

445

27.5

400

12

23

350

381

500

1300

505

29

460

16

23

400

406

640

1370

565

30

513

16

28

450

432

720

1430

615

31.5

565

20

28

500

457

720

1510

670

33

620

20

28

600

508

720

–

780

36

725

20

31

| Size (mm) | FF | ØW | H | ØFD | FT | k | n | Ød |

|---|---|---|---|---|---|---|---|---|

| 50 | 178 | 225 | 320 | 165 | 16 | 125 | 4 | 19 |

| 65 | 190 | 225 | 375 | 185 | 16 | 145 | 4 | 19 |

| 80 | 203 | 225 | 422 | 200 | 21 | 160 | 4 | 19 |

| 100 | 229 | 320 | 490 | 220 | 22 | 180 | 8 | 19 |

| 125 | 254 | 320 | 560 | 250 | 22.5 | 210 | 8 | 19 |

| 150 | 267 | 320 | 640 | 285 | 23 | 240 | 8 | 23 |

| 200 | 292 | 360 | 782 | 340 | 24.5 | 295 | 8 | 23 |

| 250 | 330 | 400 | 1040 | 395 | 26 | 350 | 12 | 23 |

| 300 | 356 | 400 | 1170 | 445 | 27.5 | 400 | 12 | 23 |

| 350 | 381 | 500 | 1300 | 505 | 29 | 460 | 16 | 23 |

| 400 | 406 | 640 | 1370 | 565 | 30 | 513 | 16 | 28 |

| 450 | 432 | 720 | 1430 | 615 | 31.5 | 565 | 20 | 28 |

| 500 | 457 | 720 | 1510 | 670 | 33 | 620 | 20 | 28 |

| 600 | 508 | 720 | – | 780 | 36 | 725 | 20 | 31 |

Products (By Standard)

Non-IBR

All Rights Reserved. Atam Valves Limited