-

Features

Body Material Cum Standard

Bronze (IBR 282 (a) (iv) Gr. B)

Product Description

Rack & Pinion Operated with Stellite Face, Supplied with Operating Key

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

Seat & Disc: 13% Cr. (SS 410) + Stellite

End Details

Flanged Ends as per BS-10 Table-H Flat Face (Undrilled)

Test Pressure

Body: 500 Psig (Hyd.)

Max. Working Pressure

250 Psig (Steam)

Max. Working Temperature

225°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Suitability

Water

Steam

Gas

Oil

Air

-

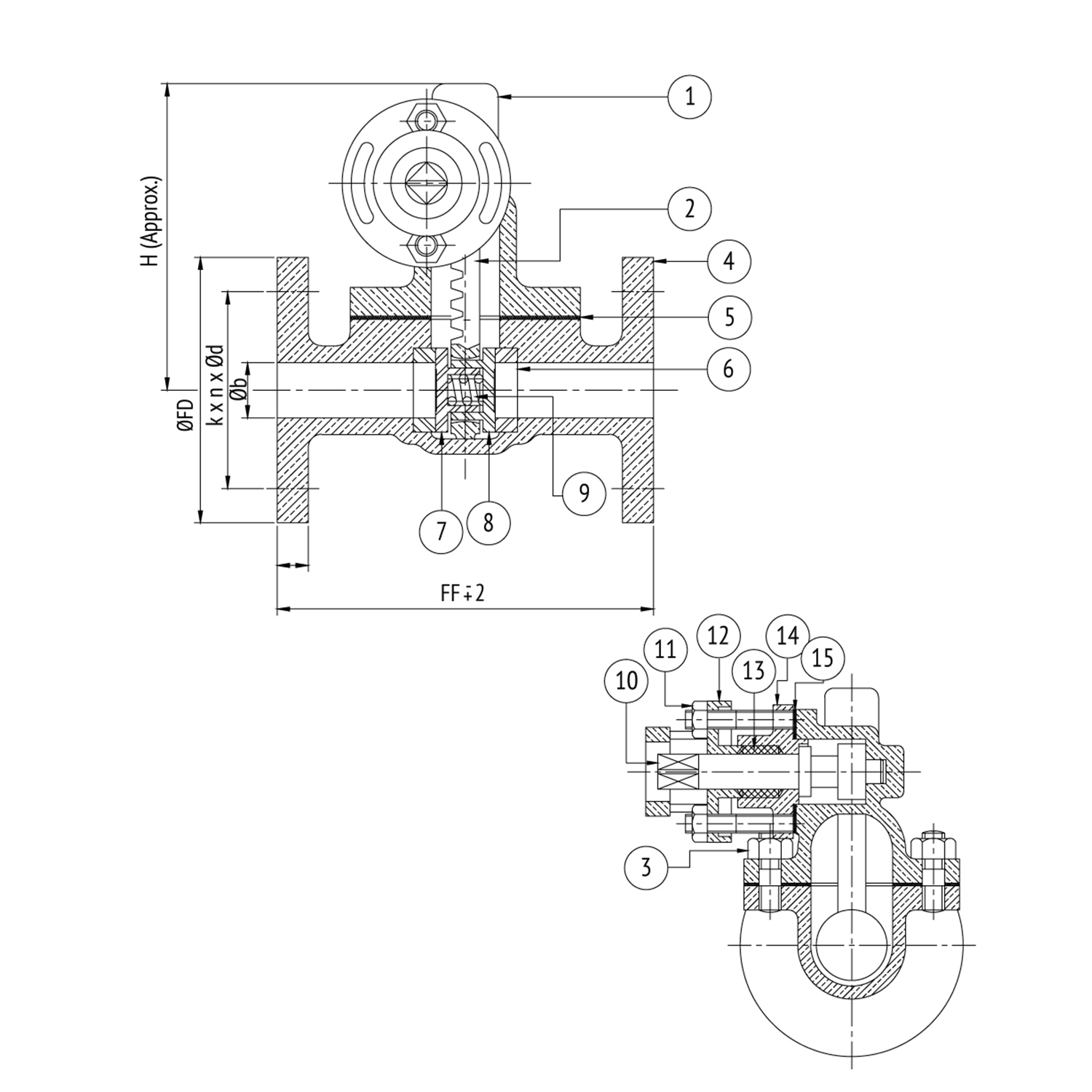

Material Combination

S.No Description No. Material Specifications 1 Bonnet 1 Bronze IBR 282 (a) (iv) Gr. B 2 Rack 1 C.A.S. ASTM A 217 Gr. CA15 3 Studs & Nuts To Suit Carbon Steel – 4 Body 1 Bronze IBR 282 (a) (iv) Gr. B 5 Gasket 1 Non Asbestos – 6 Body Seat Ring 1 Stainless Steel AISI 410 Stellited 7 Male Disc 1 Stainless Steel AISI 410 Stellited 8 Female Disc 1 Stainless Steel AISI 410 Stellited 9 Spring 1 Spring Steel – 10 Pinion 1 C.A.S. ASTM A 217 Gr. CA15 11 Studs & Nuts 2 Each Carbon Steel – 12 Gland Flange 1 S.G. Iron EN 1563 Gr.GJL 400 15 13 Gland Packing – Graphited Asbestos – 14 Stuffing Box 1 S.G. Iron EN 1563 Gr.GJL 400 15 15 Gasket 1 Non Asbestos – -

Dimensional Data

Size (mm) FF H Øb ØFD FT k n Ød 25 167 142 25 120.7 11.1 87.3 4 17.5 32 173 158 32 133.4 11.1 98.4 4 17.5 40 190 205 38 139.7 12.7 104.8 4 17.5 50 206 227 50 165.1 12.7 127 4 17.5 65 228 270 63.5 184.1 14.3 146.1 8 17.5 80 254 312 76.2 203.2 16 165 8 17.5

Features

Body Material Cum Standard

Bronze (IBR 282 (a) (iv) Gr. B)

Product Description

Rack & Pinion Operated with Stellite Face, Supplied with Operating Key

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

Seat & Disc: 13% Cr. (SS 410) + Stellite

End Details

Flanged Ends as per BS-10 Table-H Flat Face (Undrilled)

Test Pressure

Body: 500 Psig (Hyd.)

Max. Working Pressure

250 Psig (Steam)

Max. Working Temperature

225°C

Body Material Cum Standard

Bronze (IBR 282 (a) (iv) Gr. B)

Product Description

Rack & Pinion Operated with Stellite Face, Supplied with Operating Key

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

Seat & Disc: 13% Cr. (SS 410) + Stellite

End Details

Flanged Ends as per BS-10 Table-H Flat Face (Undrilled)

Test Pressure

Body: 500 Psig (Hyd.)

Max. Working Pressure

250 Psig (Steam)

Max. Working Temperature

225°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

S.No

Description

No.

Material

Specifications

1

Bonnet

1

Bronze

IBR 282 (a) (iv) Gr. B

2

Rack

1

C.A.S.

ASTM A 217 Gr. CA15

3

Studs & Nuts

To Suit

Carbon Steel

–

4

Body

1

Bronze

IBR 282 (a) (iv) Gr. B

5

Gasket

1

Non Asbestos

–

6

Body Seat Ring

1

Stainless Steel

AISI 410 Stellited

7

Male Disc

1

Stainless Steel

AISI 410 Stellited

8

Female Disc

1

Stainless Steel

AISI 410 Stellited

9

Spring

1

Spring Steel

–

10

Pinion

1

C.A.S.

ASTM A 217 Gr. CA15

11

Studs & Nuts

2 Each

Carbon Steel

–

12

Gland Flange

1

S.G. Iron

EN 1563 Gr.GJL 400 15

13

Gland Packing

–

Graphited Asbestos

–

14

Stuffing Box

1

S.G. Iron

EN 1563 Gr.GJL 400 15

15

Gasket

1

Non Asbestos

–

| S.No | Description | No. | Material | Specifications |

|---|---|---|---|---|

| 1 | Bonnet | 1 | Bronze | IBR 282 (a) (iv) Gr. B |

| 2 | Rack | 1 | C.A.S. | ASTM A 217 Gr. CA15 |

| 3 | Studs & Nuts | To Suit | Carbon Steel | – |

| 4 | Body | 1 | Bronze | IBR 282 (a) (iv) Gr. B |

| 5 | Gasket | 1 | Non Asbestos | – |

| 6 | Body Seat Ring | 1 | Stainless Steel | AISI 410 Stellited |

| 7 | Male Disc | 1 | Stainless Steel | AISI 410 Stellited |

| 8 | Female Disc | 1 | Stainless Steel | AISI 410 Stellited |

| 9 | Spring | 1 | Spring Steel | – |

| 10 | Pinion | 1 | C.A.S. | ASTM A 217 Gr. CA15 |

| 11 | Studs & Nuts | 2 Each | Carbon Steel | – |

| 12 | Gland Flange | 1 | S.G. Iron | EN 1563 Gr.GJL 400 15 |

| 13 | Gland Packing | – | Graphited Asbestos | – |

| 14 | Stuffing Box | 1 | S.G. Iron | EN 1563 Gr.GJL 400 15 |

| 15 | Gasket | 1 | Non Asbestos | – |

Dimensional Data

Size (mm)

FF

H

Øb

ØFD

FT

k

n

Ød

25

167

142

25

120.7

11.1

87.3

4

17.5

32

173

158

32

133.4

11.1

98.4

4

17.5

40

190

205

38

139.7

12.7

104.8

4

17.5

50

206

227

50

165.1

12.7

127

4

17.5

65

228

270

63.5

184.1

14.3

146.1

8

17.5

80

254

312

76.2

203.2

16

165

8

17.5

| Size (mm) | FF | H | Øb | ØFD | FT | k | n | Ød |

|---|---|---|---|---|---|---|---|---|

| 25 | 167 | 142 | 25 | 120.7 | 11.1 | 87.3 | 4 | 17.5 |

| 32 | 173 | 158 | 32 | 133.4 | 11.1 | 98.4 | 4 | 17.5 |

| 40 | 190 | 205 | 38 | 139.7 | 12.7 | 104.8 | 4 | 17.5 |

| 50 | 206 | 227 | 50 | 165.1 | 12.7 | 127 | 4 | 17.5 |

| 65 | 228 | 270 | 63.5 | 184.1 | 14.3 | 146.1 | 8 | 17.5 |

| 80 | 254 | 312 | 76.2 | 203.2 | 16 | 165 | 8 | 17.5 |

Products (By Valve Type)

Parallel Slide Blow Off Valves

All Rights Reserved. Atam Valves Limited