-

Features

Type of Pattern

Straight / Right Angle Pattern

Body Material Cum Standard

Cast Iron (IBR 86 to 93 Gr. A)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem with Backseat Arrangement, Handwheel Operated

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410)

End Details

Flanged Drilling as per BS-10 Table-H Raised Face (PN-16)

Test Pressure

Body: 24 kg/cm² (Hyd.), Seat & Back Seat : 17.6 kg/cm²

Max. Working Pressure

13 kg/cm² (Steam)

Max. Working Temperature

220°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Suitability

Water

Steam

Gas

Oil

Air

-

Material Combination

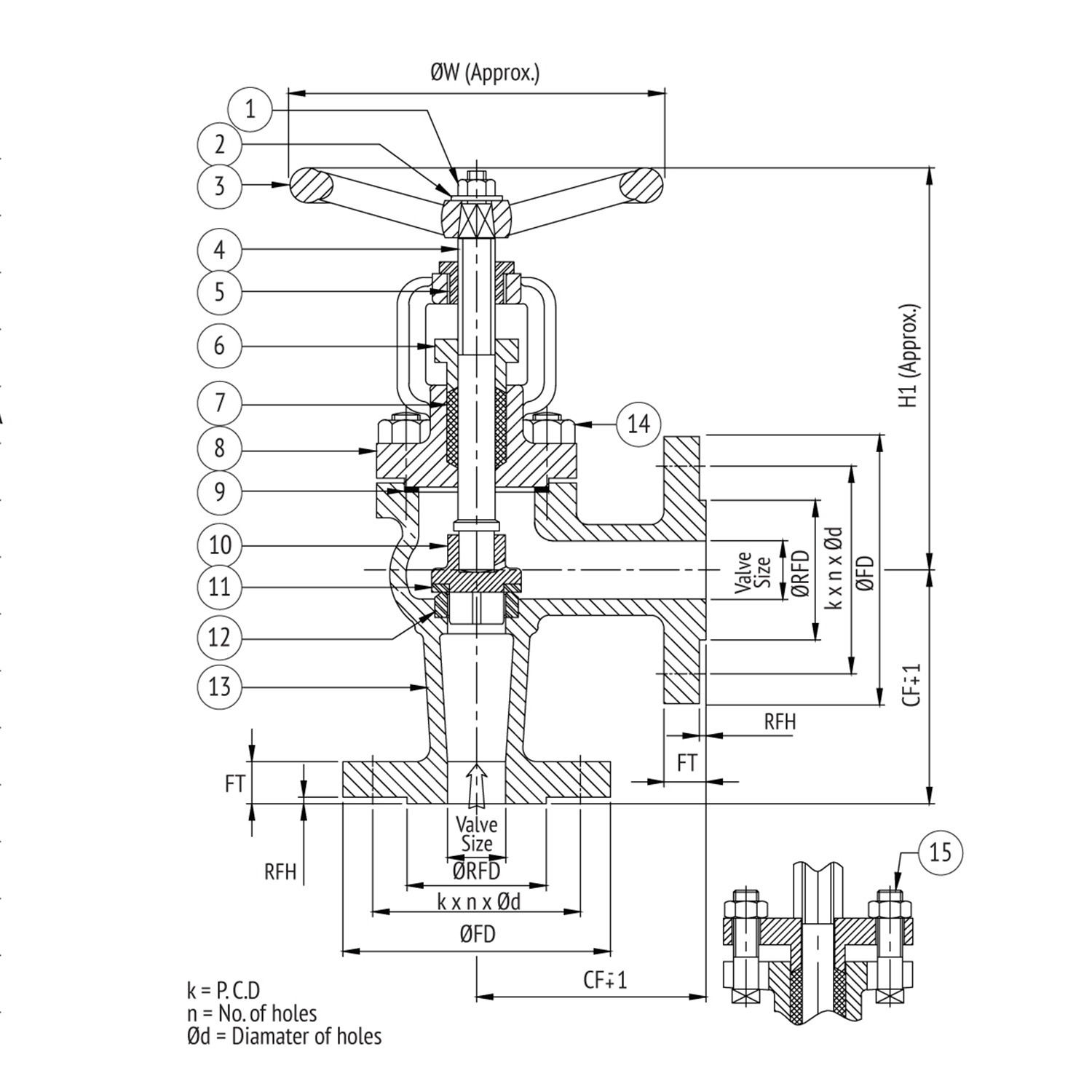

S.No Description No. Material Specifications 1 Nut 1 Carbon Steel – 2 Washer 1 Carbon Steel – 3 Handwheel 1 Cast Iron IS 210 Gr. FG200 4 Stem 1 Stainless Steel ASTM A 276 Type 410 5 Yoke Bush 1 Al. Bronze / Stainless Steel BS 1982 Gr. CC 331G / ASTM A 582 Type 416 6 Gland Flange 1 Cast Iron IBR 86 to 93 Gr.A 7 Gland Packing – Graphited Asbestos – 8 Bonnet 1 Cast Iron IBR 86 to 93 Gr.A 9 Gasket 1 C.A.F. – 10 Disc 1 Cast Iron IBR 86 to 93 Gr.A 11 Disc Ring 1 Stainless Steel ASTM A 276 Type 410 12 Body Seat Ring 1 Stainless Steel ASTM A 276 Type 410 13 Body 1 Cast Iron IBR 86 to 93 Gr.A 14 Studs & Nuts To Suit Carbon Steel – 15 T Heads Bolts & Nuts 2 Each Carbon Steel – -

Dimensional Data

Size (mm) CF H1 ØW ØFD FT ØRFD RFH k n Ød 15 90 150 100 114.3 14 46 2 82.6 4 17.5 20 95 150 100 114.3 16 56 2 82.6 4 17.5 25 100 160 100 115 16 65 3 87.3 4 17.5 32 105 170 165 140 18 76 3 98.4 4 17.5 40 115 220 165 150 18 84 3 104.8 4 17.5 50 125 260 165 165 20 99 3 127 4 17.5 65 145 280 200 185 20 118 3 146 8 17.5 80 155 300 200 203.2 22 132 3 165 8 17.5 100 175 350 250 228.6 24 156 3 190.5 8 17.5 125 200 400 250 279.4 26 184 3 235 8 22.3 150 225 430 315 304.8 26 211 3 260.4 12 22.3

Features

Type of Pattern

Straight / Right Angle Pattern

Body Material Cum Standard

Cast Iron (IBR 86 to 93 Gr. A)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem with Backseat Arrangement, Handwheel Operated

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410)

End Details

Flanged Drilling as per BS-10 Table-H Raised Face (PN-16)

Test Pressure

Body: 24 kg/cm² (Hyd.), Seat & Back Seat : 17.6 kg/cm²

Max. Working Pressure

13 kg/cm² (Steam)

Max. Working Temperature

220°C

Type of Pattern

Straight / Right Angle Pattern

Body Material Cum Standard

Cast Iron (IBR 86 to 93 Gr. A)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem with Backseat Arrangement, Handwheel Operated

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410)

End Details

Flanged Drilling as per BS-10 Table-H Raised Face (PN-16)

Test Pressure

Body: 24 kg/cm² (Hyd.), Seat & Back Seat : 17.6 kg/cm²

Max. Working Pressure

13 kg/cm² (Steam)

Max. Working Temperature

220°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

S.No

Description

No.

Material

Specifications

1

Nut

1

Carbon Steel

–

2

Washer

1

Carbon Steel

–

3

Handwheel

1

Cast Iron

IS 210 Gr. FG200

4

Stem

1

Stainless Steel

ASTM A 276 Type 410

5

Yoke Bush

1

Al. Bronze / Stainless Steel

BS 1982 Gr. CC 331G / ASTM A 582 Type 416

6

Gland Flange

1

Cast Iron

IBR 86 to 93 Gr.A

7

Gland Packing

–

Graphited Asbestos

–

8

Bonnet

1

Cast Iron

IBR 86 to 93 Gr.A

9

Gasket

1

C.A.F.

–

10

Disc

1

Cast Iron

IBR 86 to 93 Gr.A

11

Disc Ring

1

Stainless Steel

ASTM A 276 Type 410

12

Body Seat Ring

1

Stainless Steel

ASTM A 276 Type 410

13

Body

1

Cast Iron

IBR 86 to 93 Gr.A

14

Studs & Nuts

To Suit

Carbon Steel

–

15

T Heads Bolts & Nuts

2 Each

Carbon Steel

–

| S.No | Description | No. | Material | Specifications |

|---|---|---|---|---|

| 1 | Nut | 1 | Carbon Steel | – |

| 2 | Washer | 1 | Carbon Steel | – |

| 3 | Handwheel | 1 | Cast Iron | IS 210 Gr. FG200 |

| 4 | Stem | 1 | Stainless Steel | ASTM A 276 Type 410 |

| 5 | Yoke Bush | 1 | Al. Bronze / Stainless Steel | BS 1982 Gr. CC 331G / ASTM A 582 Type 416 |

| 6 | Gland Flange | 1 | Cast Iron | IBR 86 to 93 Gr.A |

| 7 | Gland Packing | – | Graphited Asbestos | – |

| 8 | Bonnet | 1 | Cast Iron | IBR 86 to 93 Gr.A |

| 9 | Gasket | 1 | C.A.F. | – |

| 10 | Disc | 1 | Cast Iron | IBR 86 to 93 Gr.A |

| 11 | Disc Ring | 1 | Stainless Steel | ASTM A 276 Type 410 |

| 12 | Body Seat Ring | 1 | Stainless Steel | ASTM A 276 Type 410 |

| 13 | Body | 1 | Cast Iron | IBR 86 to 93 Gr.A |

| 14 | Studs & Nuts | To Suit | Carbon Steel | – |

| 15 | T Heads Bolts & Nuts | 2 Each | Carbon Steel | – |

Dimensional Data

Size (mm)

CF

H1

ØW

ØFD

FT

ØRFD

RFH

k

n

Ød

15

90

150

100

114.3

14

46

2

82.6

4

17.5

20

95

150

100

114.3

16

56

2

82.6

4

17.5

25

100

160

100

115

16

65

3

87.3

4

17.5

32

105

170

165

140

18

76

3

98.4

4

17.5

40

115

220

165

150

18

84

3

104.8

4

17.5

50

125

260

165

165

20

99

3

127

4

17.5

65

145

280

200

185

20

118

3

146

8

17.5

80

155

300

200

203.2

22

132

3

165

8

17.5

100

175

350

250

228.6

24

156

3

190.5

8

17.5

125

200

400

250

279.4

26

184

3

235

8

22.3

150

225

430

315

304.8

26

211

3

260.4

12

22.3

| Size (mm) | CF | H1 | ØW | ØFD | FT | ØRFD | RFH | k | n | Ød |

|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 90 | 150 | 100 | 114.3 | 14 | 46 | 2 | 82.6 | 4 | 17.5 |

| 20 | 95 | 150 | 100 | 114.3 | 16 | 56 | 2 | 82.6 | 4 | 17.5 |

| 25 | 100 | 160 | 100 | 115 | 16 | 65 | 3 | 87.3 | 4 | 17.5 |

| 32 | 105 | 170 | 165 | 140 | 18 | 76 | 3 | 98.4 | 4 | 17.5 |

| 40 | 115 | 220 | 165 | 150 | 18 | 84 | 3 | 104.8 | 4 | 17.5 |

| 50 | 125 | 260 | 165 | 165 | 20 | 99 | 3 | 127 | 4 | 17.5 |

| 65 | 145 | 280 | 200 | 185 | 20 | 118 | 3 | 146 | 8 | 17.5 |

| 80 | 155 | 300 | 200 | 203.2 | 22 | 132 | 3 | 165 | 8 | 17.5 |

| 100 | 175 | 350 | 250 | 228.6 | 24 | 156 | 3 | 190.5 | 8 | 17.5 |

| 125 | 200 | 400 | 250 | 279.4 | 26 | 184 | 3 | 235 | 8 | 22.3 |

| 150 | 225 | 430 | 315 | 304.8 | 26 | 211 | 3 | 260.4 | 12 | 22.3 |

All Rights Reserved. Atam Valves Limited