-

Features

Type of Pattern

Right Angle Pattern

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Spring Loaded, Full Lift

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410) + Stellited Facing

End Details

Inlet Flanged Ends as per BS-10 Table-H Flat Face (Undrilled), Outlet Flanged Ends as per BS-10 Table-D Flat Face (Undrilled)

Test Pressure

Body: 500 Psig (Hyd.)

Max. Working Pressure

250 Psig (Steam)

Max. Working Temperature

400°C

Max. Set Pressure

250 Psig (Steam)

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Suitability

Water

Steam

Gas

Oil

Air

-

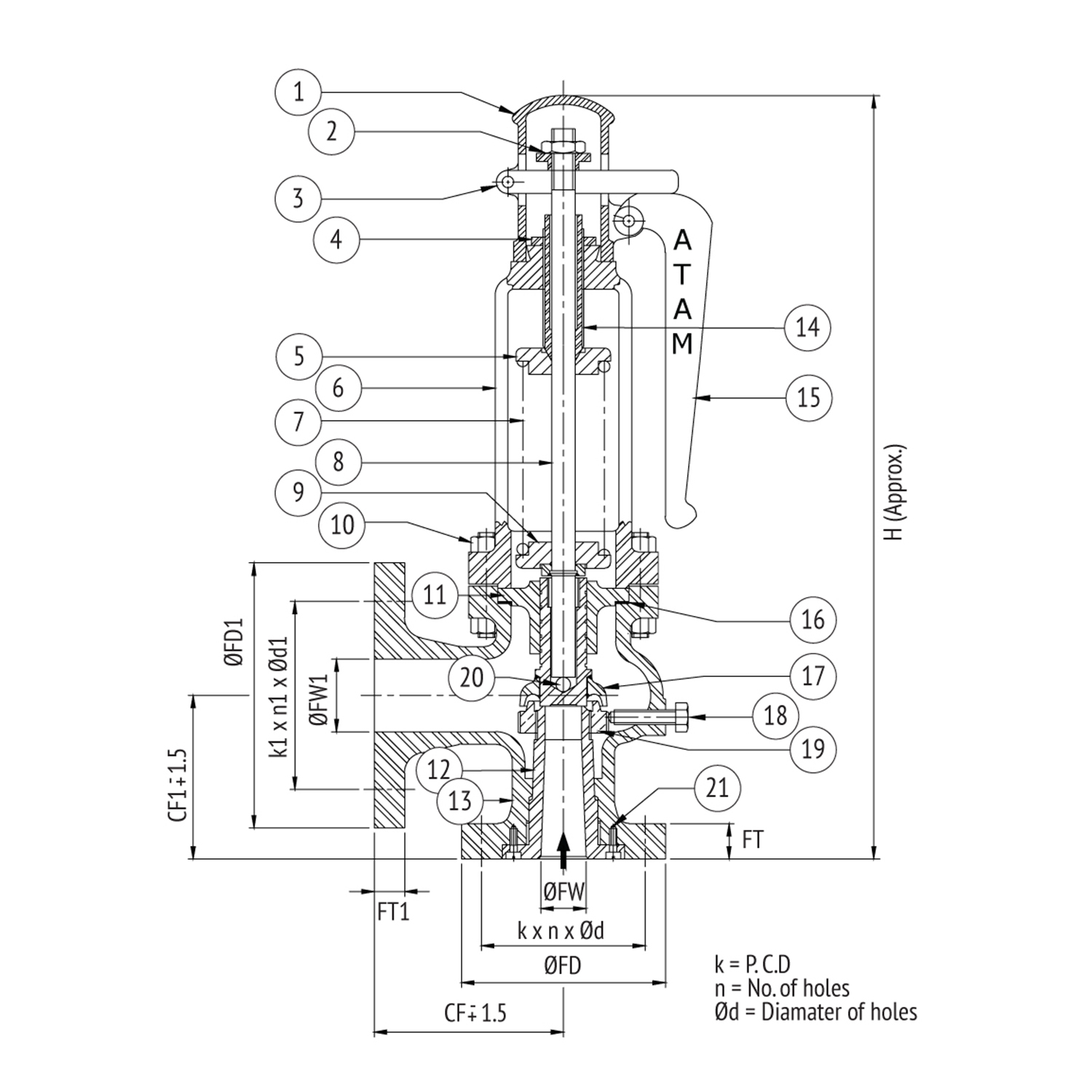

Material Combination

S.No Description No. Material Specifications 1 Cap 1 Cast Iron IBR 86 to 93 Gr. A 2 Locking Nut 1 Bronze IBR 282 (a) (iv) Gr. B 3, 6, 11 Fork, Bonnet, Disc Guide 1 C.C.S. IBR 73 to 80 4, 8 Check Nut, Stem 1 Stainless Steel AISI 410 5, 9 Upper / Lower Spring Disc 1 C.C.S. / Carbon Steel IBR 73 to 80 / – CF1+- 1.5 7, 18 Spring, Bolt 1 Carbon Steel – 10 Bolts / Studs & Nuts To Suit Carbon Steel – 12 Nozzle 1 Stainless Steel AISI 410 + Stellite 13 Body 1 C.C.S. IBR 73 to 80 14 Adjusting Screw 1 Stainless Steel AISI 410 15 Handle 1 S.G. Iron / C.I. – 16 Gasket 1 C.A.F. – 17 Disc 1 C.S.S. / S.S. ASTM A 217 Gr. CA15 / ASTM A 276 Type 410 + Stellite 19 Regualting Ring 1 Bronze IBR 282 (a) (iv) Gr. B 20 Ball 1 Stainless Steel – 21 Screw 4 Carbon Steel – -

Dimensional Data

Table – H Size (mm) CF ØFW ØFD FT k n Ød 25 x 40 100 26 120.7 14.3 87.3 4 17.5 40 x 50 130 40 139.7 17.5 104.8 4 17.5 50 x 80 140 50 165.1 19.1 127 4 17.5 80 x 100 200 76 203.2 22.3 165.1 8 17.5 100 x 150 205 100 228.6 25.4 190.5 8 17.5 Table – D

Size (mm) CF1 ØFW1 ØFD1 FT1 k1 n1 Ød1 H 25 x 40 95 40 133.4 12.7 98.4 4 14.3 435 40 x 50 112 50 152.4 14.3 114.3 4 17.5 520 50 x 80 130 76 184.2 14.3 146.1 4 17.5 580 80 x 100 190 100 215.9 17.5 177.8 4 17.5 860 100 x 150 220 152 279.4 17.5 235 8 17.5 1035

Features

Type of Pattern

Right Angle Pattern

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Spring Loaded, Full Lift

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410) + Stellited Facing

End Details

Inlet Flanged Ends as per BS-10 Table-H Flat Face (Undrilled), Outlet Flanged Ends as per BS-10 Table-D Flat Face (Undrilled)

Test Pressure

Body: 500 Psig (Hyd.)

Max. Working Pressure

250 Psig (Steam)

Max. Working Temperature

400°C

Max. Set Pressure

250 Psig (Steam)

Type of Pattern

Right Angle Pattern

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Spring Loaded, Full Lift

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410) + Stellited Facing

End Details

Inlet Flanged Ends as per BS-10 Table-H Flat Face (Undrilled), Outlet Flanged Ends as per BS-10 Table-D Flat Face (Undrilled)

Test Pressure

Body: 500 Psig (Hyd.)

Max. Working Pressure

250 Psig (Steam)

Max. Working Temperature

400°C

Max. Set Pressure

250 Psig (Steam)

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

S.No

Description

No.

Material

Specifications

1

Cap

1

Cast Iron

IBR 86 to 93 Gr. A

2

Locking Nut

1

Bronze

IBR 282 (a) (iv) Gr. B

3, 6, 11

Fork, Bonnet, Disc Guide

1

C.C.S.

IBR 73 to 80

4, 8

Check Nut, Stem

1

Stainless Steel

AISI 410

5, 9

Upper / Lower Spring Disc

1

C.C.S. / Carbon Steel

IBR 73 to 80 / – CF1+- 1.5

7, 18

Spring, Bolt

1

Carbon Steel

–

10

Bolts / Studs & Nuts

To Suit

Carbon Steel

–

12

Nozzle

1

Stainless Steel

AISI 410 + Stellite

13

Body

1

C.C.S.

IBR 73 to 80

14

Adjusting Screw

1

Stainless Steel

AISI 410

15

Handle

1

S.G. Iron / C.I.

–

16

Gasket

1

C.A.F.

–

17

Disc

1

C.S.S. / S.S.

ASTM A 217 Gr. CA15 / ASTM A 276 Type 410 + Stellite

19

Regualting Ring

1

Bronze

IBR 282 (a) (iv) Gr. B

20

Ball

1

Stainless Steel

–

21

Screw

4

Carbon Steel

–

| S.No | Description | No. | Material | Specifications |

|---|---|---|---|---|

| 1 | Cap | 1 | Cast Iron | IBR 86 to 93 Gr. A |

| 2 | Locking Nut | 1 | Bronze | IBR 282 (a) (iv) Gr. B |

| 3, 6, 11 | Fork, Bonnet, Disc Guide | 1 | C.C.S. | IBR 73 to 80 |

| 4, 8 | Check Nut, Stem | 1 | Stainless Steel | AISI 410 |

| 5, 9 | Upper / Lower Spring Disc | 1 | C.C.S. / Carbon Steel | IBR 73 to 80 / – CF1+- 1.5 |

| 7, 18 | Spring, Bolt | 1 | Carbon Steel | – |

| 10 | Bolts / Studs & Nuts | To Suit | Carbon Steel | – |

| 12 | Nozzle | 1 | Stainless Steel | AISI 410 + Stellite |

| 13 | Body | 1 | C.C.S. | IBR 73 to 80 |

| 14 | Adjusting Screw | 1 | Stainless Steel | AISI 410 |

| 15 | Handle | 1 | S.G. Iron / C.I. | – |

| 16 | Gasket | 1 | C.A.F. | – |

| 17 | Disc | 1 | C.S.S. / S.S. | ASTM A 217 Gr. CA15 / ASTM A 276 Type 410 + Stellite |

| 19 | Regualting Ring | 1 | Bronze | IBR 282 (a) (iv) Gr. B |

| 20 | Ball | 1 | Stainless Steel | – |

| 21 | Screw | 4 | Carbon Steel | – |

Dimensional Data

Table – H

Size (mm)

CF

ØFW

ØFD

FT

k

n

Ød

25 x 40

100

26

120.7

14.3

87.3

4

17.5

40 x 50

130

40

139.7

17.5

104.8

4

17.5

50 x 80

140

50

165.1

19.1

127

4

17.5

80 x 100

200

76

203.2

22.3

165.1

8

17.5

100 x 150

205

100

228.6

25.4

190.5

8

17.5

Table – D

Size (mm)

CF1

ØFW1

ØFD1

FT1

k1

n1

Ød1

H

25 x 40

95

40

133.4

12.7

98.4

4

14.3

435

40 x 50

112

50

152.4

14.3

114.3

4

17.5

520

50 x 80

130

76

184.2

14.3

146.1

4

17.5

580

80 x 100

190

100

215.9

17.5

177.8

4

17.5

860

100 x 150

220

152

279.4

17.5

235

8

17.5

1035

| Size (mm) | CF | ØFW | ØFD | FT | k | n | Ød |

|---|---|---|---|---|---|---|---|

| 25 x 40 | 100 | 26 | 120.7 | 14.3 | 87.3 | 4 | 17.5 |

| 40 x 50 | 130 | 40 | 139.7 | 17.5 | 104.8 | 4 | 17.5 |

| 50 x 80 | 140 | 50 | 165.1 | 19.1 | 127 | 4 | 17.5 |

| 80 x 100 | 200 | 76 | 203.2 | 22.3 | 165.1 | 8 | 17.5 |

| 100 x 150 | 205 | 100 | 228.6 | 25.4 | 190.5 | 8 | 17.5 |

Table – D

| Size (mm) | CF1 | ØFW1 | ØFD1 | FT1 | k1 | n1 | Ød1 | H |

|---|---|---|---|---|---|---|---|---|

| 25 x 40 | 95 | 40 | 133.4 | 12.7 | 98.4 | 4 | 14.3 | 435 |

| 40 x 50 | 112 | 50 | 152.4 | 14.3 | 114.3 | 4 | 17.5 | 520 |

| 50 x 80 | 130 | 76 | 184.2 | 14.3 | 146.1 | 4 | 17.5 | 580 |

| 80 x 100 | 190 | 100 | 215.9 | 17.5 | 177.8 | 4 | 17.5 | 860 |

| 100 x 150 | 220 | 152 | 279.4 | 17.5 | 235 | 8 | 17.5 | 1035 |

Products (By Standard)

IBR Approved

All Rights Reserved. Atam Valves Limited