-

Features

Product Standard

BS 1873 / ASME B16.34

Testing Standard

API-598

Pressure / Class Rating

Class-150

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem, Handwheel Operated

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410)

End Details

Flanged Ends as per ASME B16.5 Class-150 Raised Face (Drilled)

Test Pressure

Body: 30 Bar (Hyd.), Seat: 22 Bar (Hyd.), Seat: 7 Bar (Air)

Max. Working Temperature

425°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Other trim material combinations are available on request.

Suitability

Water

Steam

Gas

Oil

Air

-

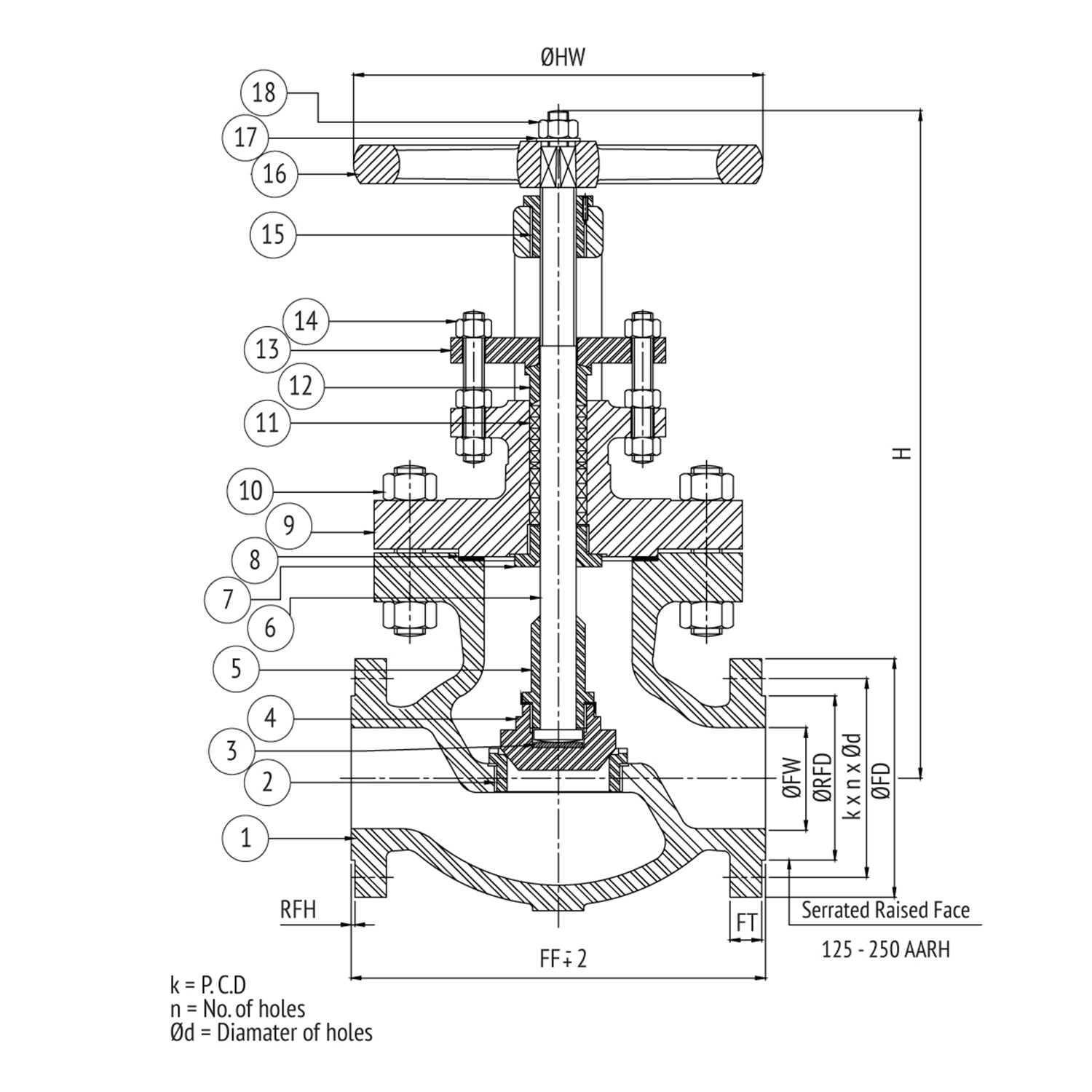

Material Combination

P.No. Name of Part Material Specification Nos. 1 Body C.C.S ASTM A216 Gr. WCB 1 2 Body Seat Ring C.C.S/F.S.S. ASTM A216 Gr. WCB + 13% Cr. Weld Deposite/ ASTM A182 Gr. F6a 2 3 Thrust Plate Hardened Steel – 1 4 Disc C.C.S./ C.A.S. / S.S. ASTM A216 Gr. WCB + 13% Cr. Weld Deposite/ ASTM A217 GR. CA 15/ ASTM A 276 TYPE 410 1 5 Disc Nut S.S. ASTM A 276 TYPE 410 1 6 Stem S.S. ASTM A 276 TYPE 410 1 7 Back Seat Bush S.S. ASTM A276 TYPE 410 To Suit 8 Gasket Spiral Wound S.S. 304 Graphoil Filler With Inner Ring (C.S. or S.S. 304) – 1 9 Bonnet C.C.S. ASTM A 216 Gr. WCB 1 10 Studs & Nuts Alloy Steel/ H.T Steel ASTM A193 Gr. B7/ASTM A194 Gr. 2H 1 11 Gland Packing Flexible Graphite – 12 Gland Follower S.S. ASTM A276 TYPE 410 1 13 Gland Flange C.C.S./ C.S. ASTM A216 Gr. WCB/ – 1 14 Gland Studs & Nuts Alloy Steel/ H.T Steel ASTM A193 Gr. B7/ASTM A194 Gr. 2H 2/4 15 Yoke Bush Al. Bronze BS EN 1982 Gr. CC331G 1 18 Handwheel M.I./ D.I. ASTM A338/ ASTM A536 Gr. 80-55-06 1 17 Washer Carbon Steel – 1 18 Nut for Handwheel Carbon Steel – 1 -

Dimensional Data

Nominal Size (mm) FF FT ØFW ØRFD RFH ØFD K n Ød ØHW H 15 108 8 15 34.9 2 90 60.3 4 5/8″ 100 185 20 117 9 20 42.9 2 100 70 4 5/8″ 100 190 25 127 9.6 25 50.8 2 110 79.4 4 5/8″ 160 220 40 165 12.7 38 73 2 125 98.4 4 5/8″ 203 240 50 203 14.3 51 92.1 2 150 120.7 4 3/4″ 203 270 65 216 15.9 64 104.8 2 180 139.7 4 3/4″ 229 310 80 241 17.5 76 127 2 190 152.4 4 3/4″ 229 350 100 292 22.3 102 157.2 2 230 190.5 8 3/4″ 254 400 125 356 22.3 127 185.7 2 255 215.9 8 7/8″ 254 425 150 406 23.9 152 215.9 2 280 241.3 8 7/8″ 305 500 200 495 27 203 269.9 2 345 298.5 8 7/8″ 457 590 250 622 28.6 254 323.8 2 405 362 12 1″ 560 740 k – P.C.D; n – Number of Holes; Ød – Diameter of Holes

Features

Product Standard

BS 1873 / ASME B16.34

Testing Standard

API-598

Pressure / Class Rating

Class-150

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem, Handwheel Operated

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410)

End Details

Flanged Ends as per ASME B16.5 Class-150 Raised Face (Drilled)

Test Pressure

Body: 30 Bar (Hyd.), Seat: 22 Bar (Hyd.), Seat: 7 Bar (Air)

Max. Working Temperature

425°C

Product Standard

BS 1873 / ASME B16.34

Testing Standard

API-598

Pressure / Class Rating

Class-150

Body Material Cum Standard

Cast Carbon Steel (ASTM A216 Gr. WCB)

Product Description

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem, Handwheel Operated

Type of Seat

Renewable Seat

Type of Disc

Renewable Disc

Trim

13% Cr. (SS 410)

End Details

Flanged Ends as per ASME B16.5 Class-150 Raised Face (Drilled)

Test Pressure

Body: 30 Bar (Hyd.), Seat: 22 Bar (Hyd.), Seat: 7 Bar (Air)

Max. Working Temperature

425°C

Notes

Test Certificate in Form III-C as per IBR is furnished with every supply.

Other trim material combinations are available on request.

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

P.No.

Name of Part

Material

Specification

Nos.

1

Body

C.C.S

ASTM A216 Gr. WCB

1

2

Body Seat Ring

C.C.S/F.S.S.

ASTM A216 Gr. WCB + 13% Cr. Weld Deposite/ ASTM A182 Gr. F6a

2

3

Thrust Plate

Hardened Steel

–

1

4

Disc

C.C.S./ C.A.S. / S.S.

ASTM A216 Gr. WCB + 13% Cr. Weld Deposite/ ASTM A217 GR. CA 15/ ASTM A 276 TYPE 410

1

5

Disc Nut

S.S.

ASTM A 276 TYPE 410

1

6

Stem

S.S.

ASTM A 276 TYPE 410

1

7

Back Seat Bush

S.S.

ASTM A276 TYPE 410

To Suit

8

Gasket

Spiral Wound S.S. 304 Graphoil Filler With Inner Ring (C.S. or S.S. 304)

–

1

9

Bonnet

C.C.S.

ASTM A 216 Gr. WCB

1

10

Studs & Nuts

Alloy Steel/ H.T Steel

ASTM A193 Gr. B7/ASTM A194 Gr. 2H

1

11

Gland Packing

Flexible Graphite

–

12

Gland Follower

S.S.

ASTM A276 TYPE 410

1

13

Gland Flange

C.C.S./ C.S.

ASTM A216 Gr. WCB/ –

1

14

Gland Studs & Nuts

Alloy Steel/ H.T Steel

ASTM A193 Gr. B7/ASTM A194 Gr. 2H

2/4

15

Yoke Bush

Al. Bronze

BS EN 1982 Gr. CC331G

1

18

Handwheel

M.I./ D.I.

ASTM A338/ ASTM A536 Gr. 80-55-06

1

17

Washer

Carbon Steel

–

1

18

Nut for Handwheel

Carbon Steel

–

1

| P.No. | Name of Part | Material | Specification | Nos. |

|---|---|---|---|---|

| 1 | Body | C.C.S | ASTM A216 Gr. WCB | 1 |

| 2 | Body Seat Ring | C.C.S/F.S.S. | ASTM A216 Gr. WCB + 13% Cr. Weld Deposite/ ASTM A182 Gr. F6a | 2 |

| 3 | Thrust Plate | Hardened Steel | – | 1 |

| 4 | Disc | C.C.S./ C.A.S. / S.S. | ASTM A216 Gr. WCB + 13% Cr. Weld Deposite/ ASTM A217 GR. CA 15/ ASTM A 276 TYPE 410 | 1 |

| 5 | Disc Nut | S.S. | ASTM A 276 TYPE 410 | 1 |

| 6 | Stem | S.S. | ASTM A 276 TYPE 410 | 1 |

| 7 | Back Seat Bush | S.S. | ASTM A276 TYPE 410 | To Suit |

| 8 | Gasket | Spiral Wound S.S. 304 Graphoil Filler With Inner Ring (C.S. or S.S. 304) | – | 1 |

| 9 | Bonnet | C.C.S. | ASTM A 216 Gr. WCB | 1 |

| 10 | Studs & Nuts | Alloy Steel/ H.T Steel | ASTM A193 Gr. B7/ASTM A194 Gr. 2H | 1 |

| 11 | Gland Packing | Flexible Graphite | – | |

| 12 | Gland Follower | S.S. | ASTM A276 TYPE 410 | 1 |

| 13 | Gland Flange | C.C.S./ C.S. | ASTM A216 Gr. WCB/ – | 1 |

| 14 | Gland Studs & Nuts | Alloy Steel/ H.T Steel | ASTM A193 Gr. B7/ASTM A194 Gr. 2H | 2/4 |

| 15 | Yoke Bush | Al. Bronze | BS EN 1982 Gr. CC331G | 1 |

| 18 | Handwheel | M.I./ D.I. | ASTM A338/ ASTM A536 Gr. 80-55-06 | 1 |

| 17 | Washer | Carbon Steel | – | 1 |

| 18 | Nut for Handwheel | Carbon Steel | – | 1 |

Dimensional Data

Nominal Size (mm)

FF

FT

ØFW

ØRFD

RFH

ØFD

K

n

Ød

ØHW

H

15

108

8

15

34.9

2

90

60.3

4

5/8″

100

185

20

117

9

20

42.9

2

100

70

4

5/8″

100

190

25

127

9.6

25

50.8

2

110

79.4

4

5/8″

160

220

40

165

12.7

38

73

2

125

98.4

4

5/8″

203

240

50

203

14.3

51

92.1

2

150

120.7

4

3/4″

203

270

65

216

15.9

64

104.8

2

180

139.7

4

3/4″

229

310

80

241

17.5

76

127

2

190

152.4

4

3/4″

229

350

100

292

22.3

102

157.2

2

230

190.5

8

3/4″

254

400

125

356

22.3

127

185.7

2

255

215.9

8

7/8″

254

425

150

406

23.9

152

215.9

2

280

241.3

8

7/8″

305

500

200

495

27

203

269.9

2

345

298.5

8

7/8″

457

590

250

622

28.6

254

323.8

2

405

362

12

1″

560

740

k – P.C.D; n – Number of Holes; Ød – Diameter of Holes

| Nominal Size (mm) | FF | FT | ØFW | ØRFD | RFH | ØFD | K | n | Ød | ØHW | H |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 108 | 8 | 15 | 34.9 | 2 | 90 | 60.3 | 4 | 5/8″ | 100 | 185 |

| 20 | 117 | 9 | 20 | 42.9 | 2 | 100 | 70 | 4 | 5/8″ | 100 | 190 |

| 25 | 127 | 9.6 | 25 | 50.8 | 2 | 110 | 79.4 | 4 | 5/8″ | 160 | 220 |

| 40 | 165 | 12.7 | 38 | 73 | 2 | 125 | 98.4 | 4 | 5/8″ | 203 | 240 |

| 50 | 203 | 14.3 | 51 | 92.1 | 2 | 150 | 120.7 | 4 | 3/4″ | 203 | 270 |

| 65 | 216 | 15.9 | 64 | 104.8 | 2 | 180 | 139.7 | 4 | 3/4″ | 229 | 310 |

| 80 | 241 | 17.5 | 76 | 127 | 2 | 190 | 152.4 | 4 | 3/4″ | 229 | 350 |

| 100 | 292 | 22.3 | 102 | 157.2 | 2 | 230 | 190.5 | 8 | 3/4″ | 254 | 400 |

| 125 | 356 | 22.3 | 127 | 185.7 | 2 | 255 | 215.9 | 8 | 7/8″ | 254 | 425 |

| 150 | 406 | 23.9 | 152 | 215.9 | 2 | 280 | 241.3 | 8 | 7/8″ | 305 | 500 |

| 200 | 495 | 27 | 203 | 269.9 | 2 | 345 | 298.5 | 8 | 7/8″ | 457 | 590 |

| 250 | 622 | 28.6 | 254 | 323.8 | 2 | 405 | 362 | 12 | 1″ | 560 | 740 |

k – P.C.D; n – Number of Holes; Ød – Diameter of Holes

Products (By End Connection)

Flanged

All Rights Reserved. Atam Valves Limited