-

Features

Product Standard

BS EN 17292

Body Material Cum Standard

Cast Stainless Steel (ASTM A351 Gr. CF8M)

Port Opening

Full Bore

Product Description

Two Piece Design, Lever Operated (Blow Out Proof Stem)

Type of Seat

Renewable Seat

Trim

Ball & Stem: Stainless Steel (AISI 316), PTFE Seats

End Details

Screwed Female BSP Parallel Threads (BS-21), Socket Welded Ends as per ASME B16.11

Test Pressure

Body: 2000 Psig (Hyd.), Seat: 1000 Psig (Hyd.), Seat: 100 Psig (Air)

Max. Working Pressure

150 Psig (Steam)

Notes

Suitable for steam service with specialized PTFE.

Can be provided with Glass Filled PTFE, Graphite Blended PTFE & PEEK Seats on request.

Other screwed end specifications can be provided on request.

Suitability

Water

Steam

Gas

Oil

Air

-

Material Combination

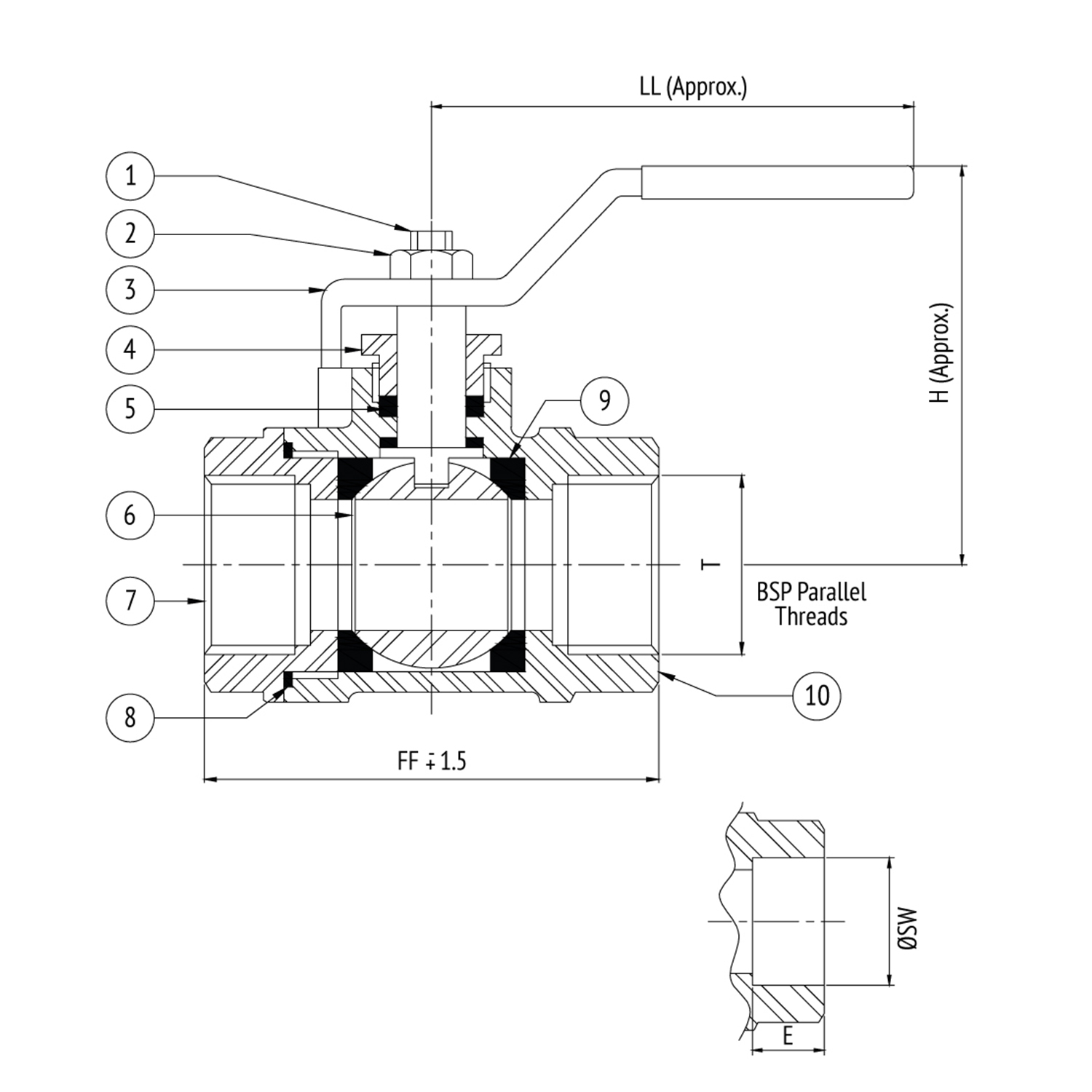

S.No Description No. Material Specifications 1 Stem 1 Stainless Steel AISI 316 2 Locking Nut 1 Stainless Steel AISI 316 3 Lever 1 Stainless Steel Sheet PVC Coated 4 Gland 1 Stainless Steel AISI 316 5 Packing Ring – PTFE – 6 Ball 1 C.S.S. ASTM A351 Gr. CF8M 7 Body Connector 1 C.S.S. ASTM A351 Gr. CF8M 8 Gasket 1 PTFE – 9 Seat 2 PTFE – 10 Body 1 C.S.S. ASTM A351 Gr. CF8M -

Dimensional Data

Size (mm) FF LL H T E ØSW 8 60 100 50 1/4” 9.5 14.6 / 14.2 10 60 100 50 3/8“ 9.5 18.0 / 17.6 15 62 125 50 1/2” 9.5 22.2 / 21.8 20 75 125 55 3/4” 12.5 27.6 / 27.6 25 85 150 60 1” 12.5 34.3 / 33.9 32 95 170 75 1.1/4” 12.5 43.1 / 42.7 40 105 220 95 1.1/2” 12.5 49.2 / 48.8 50 125 260 100 2” 16 61.7 / 61.2

Features

Product Standard

BS EN 17292

Body Material Cum Standard

Cast Stainless Steel (ASTM A351 Gr. CF8M)

Port Opening

Full Bore

Product Description

Two Piece Design, Lever Operated (Blow Out Proof Stem)

Type of Seat

Renewable Seat

Trim

Ball & Stem: Stainless Steel (AISI 316), PTFE Seats

End Details

Screwed Female BSP Parallel Threads (BS-21), Socket Welded Ends as per ASME B16.11

Test Pressure

Body: 2000 Psig (Hyd.), Seat: 1000 Psig (Hyd.), Seat: 100 Psig (Air)

Max. Working Pressure

150 Psig (Steam)

Product Standard

BS EN 17292

Body Material Cum Standard

Cast Stainless Steel (ASTM A351 Gr. CF8M)

Port Opening

Full Bore

Product Description

Two Piece Design, Lever Operated (Blow Out Proof Stem)

Type of Seat

Renewable Seat

Trim

Ball & Stem: Stainless Steel (AISI 316), PTFE Seats

End Details

Screwed Female BSP Parallel Threads (BS-21), Socket Welded Ends as per ASME B16.11

Test Pressure

Body: 2000 Psig (Hyd.), Seat: 1000 Psig (Hyd.), Seat: 100 Psig (Air)

Max. Working Pressure

150 Psig (Steam)

Notes

Suitable for steam service with specialized PTFE.

Can be provided with Glass Filled PTFE, Graphite Blended PTFE & PEEK Seats on request.

Other screwed end specifications can be provided on request.

Suitability

Water

Steam

Gas

Oil

Air

Material Combination

S.No

Description

No.

Material

Specifications

1

Stem

1

Stainless Steel

AISI 316

2

Locking Nut

1

Stainless Steel

AISI 316

3

Lever

1

Stainless Steel Sheet

PVC Coated

4

Gland

1

Stainless Steel

AISI 316

5

Packing Ring

–

PTFE

–

6

Ball

1

C.S.S.

ASTM A351 Gr. CF8M

7

Body Connector

1

C.S.S.

ASTM A351 Gr. CF8M

8

Gasket

1

PTFE

–

9

Seat

2

PTFE

–

10

Body

1

C.S.S.

ASTM A351 Gr. CF8M

| S.No | Description | No. | Material | Specifications |

|---|---|---|---|---|

| 1 | Stem | 1 | Stainless Steel | AISI 316 |

| 2 | Locking Nut | 1 | Stainless Steel | AISI 316 |

| 3 | Lever | 1 | Stainless Steel Sheet | PVC Coated |

| 4 | Gland | 1 | Stainless Steel | AISI 316 |

| 5 | Packing Ring | – | PTFE | – |

| 6 | Ball | 1 | C.S.S. | ASTM A351 Gr. CF8M |

| 7 | Body Connector | 1 | C.S.S. | ASTM A351 Gr. CF8M |

| 8 | Gasket | 1 | PTFE | – |

| 9 | Seat | 2 | PTFE | – |

| 10 | Body | 1 | C.S.S. | ASTM A351 Gr. CF8M |

Dimensional Data

Size (mm)

FF

LL

H

T

E

ØSW

8

60

100

50

1/4”

9.5

14.6 / 14.2

10

60

100

50

3/8“

9.5

18.0 / 17.6

15

62

125

50

1/2”

9.5

22.2 / 21.8

20

75

125

55

3/4”

12.5

27.6 / 27.6

25

85

150

60

1”

12.5

34.3 / 33.9

32

95

170

75

1.1/4”

12.5

43.1 / 42.7

40

105

220

95

1.1/2”

12.5

49.2 / 48.8

50

125

260

100

2”

16

61.7 / 61.2

| Size (mm) | FF | LL | H | T | E | ØSW |

|---|---|---|---|---|---|---|

| 8 | 60 | 100 | 50 | 1/4” | 9.5 | 14.6 / 14.2 |

| 10 | 60 | 100 | 50 | 3/8“ | 9.5 | 18.0 / 17.6 |

| 15 | 62 | 125 | 50 | 1/2” | 9.5 | 22.2 / 21.8 |

| 20 | 75 | 125 | 55 | 3/4” | 12.5 | 27.6 / 27.6 |

| 25 | 85 | 150 | 60 | 1” | 12.5 | 34.3 / 33.9 |

| 32 | 95 | 170 | 75 | 1.1/4” | 12.5 | 43.1 / 42.7 |

| 40 | 105 | 220 | 95 | 1.1/2” | 12.5 | 49.2 / 48.8 |

| 50 | 125 | 260 | 100 | 2” | 16 | 61.7 / 61.2 |

All Rights Reserved. Atam Valves Limited